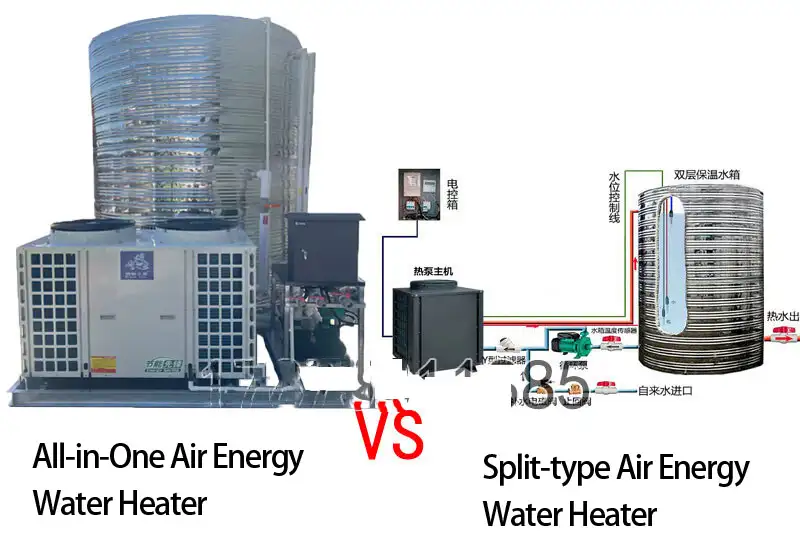

The image you uploaded is a comparison chart themed around “All-in-One Air Energy Water Heater VS Split-type Air Energy Water Heater”, detailing the advantages and disadvantages of both types. Here's an in-depth translation:

---

Left Side: All-in-One Air Energy Water Heater (Advantages)

-

No installation required; just connect water and power to use

→ Indicates that this product is plug-and-play, with simple installation suitable for users who require minimal setup or want quick deployment. -

Built-in circulation pump and booster pump for automatic circulation and pressure boosting

→ Integrated design eliminates the need for additional pumps, ensuring more stable system operation and automated pressure adjustment. -

Built-in engineering electrical control cabinet system for automatic water supply and return

→ Smart control system enhances user experience and energy-saving effects through automation management. -

Imported circulation pump and filter valve for easy observation and cleaning of scale

→ Utilizes high-quality components for easier maintenance, prolonging equipment life and simplifying routine cleaning. -

Equipped with ladder for convenient inspection, cleaning, and maintenance; aesthetically pleasing appearance

→ Humanized design considers post-installation maintenance needs while maintaining a tidy and attractive look. -

Professionally assembled as an integrated unit by engineers, facilitating hoisting, transportation, and overall handling

→ Prefabricated integration at the factory ensures high efficiency in transport and installation, suitable for large spaces or complex environments.

Right Side: Disadvantages of Split-type Air Energy Water Heaters

-

Requires professional air energy installers for on-site installation

→ Installation is complicated, dependent on technical personnel, time-consuming, and potentially more costly. -

Requires separate configuration of circulation pumps, booster pumps, and fittings

→ Users need to purchase accessories separately, increasing budget and selection difficulty, with potential compatibility issues. -

Prone to freezing and cracking of circulation pumps and heat exchangers in winter

→ In cold regions, there are safety hazards; winter anti-freeze measures must be in place to avoid equipment damage. -

Difficult to observe and clean scale on heat exchangers

→ Maintenance is challenging, affecting thermal efficiency over long-term use and increasing repair frequency. -

Installation quality greatly affects performance; not aesthetically pleasing and prone to faults

→ Installation quality directly impacts performance, and a dispersed structure leads to poor overall appearance with multiple connection points indicating higher fault risk.

Summary Comparison

| Comparison Aspect | All-in-One | Split-Type |

|---|---|---|

| Ease of Installation | ✅ Plug-and-play | ❌ Requires professional installation |

| Component Integration | ✅ Fully built-in | ❌ External multiple components |

| Maintenance Convenience | ✅ Easy to observe and clean | ❌ Difficult to maintain |

| Cold Resistance | ✅ Better (frost protection design) | ❌ Prone to freeze cracking in winter |

| Appearance & Structure | ✅ Aesthetically pleasing and tidy | ❌ Loose structure, not aesthetically pleasing |

| Reliability | ✅ Lower failure rate | ❌ More connection points, prone to problems |

Conclusion and Recommendations

- If you seek hassle-free, efficient, aesthetically pleasing, and easy-to-maintain solutions, especially in northern cold regions or locations with installation constraints, the all-in-one air energy water heater is the better choice.

- The split-type air energy water heater is more suitable for scenarios requiring professional technical team support, ample budgets, and high customization needs such as hotels or community centralized heating projects. However, it comes with higher installation and post-maintenance costs.

✅ Overall, the all-in-one model excels in intelligence, integration, and user experience, particularly fitting for household and individual users; whereas split-type models still hold value in certain specific industrial or commercial applications.

Here is the English translation of the table in a clean, structured format:

Technical Specifications Table

| Parameter | KFRS-030C (Top-Blow Type) | KFRS-050C (Top-Blow Type) | KFRS-100C (Top-Blow Type) |

|---|---|---|---|

| Rated Heating Capacity (kW) | 11.4 | 19.3 | 39.5 |

| Rated Water Production (L/h) | 245 | 415 | 850 |

| Rated Outlet Water Temperature (°C) | 55 | 55 | 55 |

| Maximum Outlet Water Temperature (°C) | 60 | 60 | 60 |

| Unit Dimensions (L×W×H, mm) | 710×810×840 | 855×775×1095 | 1450×770×1180 |

| Weight (kg) | 105 | 140 | 300 |

| Noise Level (dB(A)) | 55 | 58 | 65 |

| Electric Shock Protection Class | Class I | Class I | Class I |

| Protection Rating | IPX4 | IPX4 | IPX4 |

| Refrigerant | R22 | R22 | R22 |

| Circulating Water Flow Rate (m³/h) | 2.5 | 4.0 | 8.0 |

| Water Side Pressure Loss (kPa) | 48.0 | 50.0 | 52.0 |

| System Design Pressure (MPa) | 2.8 | 2.8 | 2.8 |

| Water System Working Pressure (MPa) | 0.5 | 0.5 | 0.5 |

| Inlet/Outlet Pipe Size | DN25 (Internal Thread Connection) | DN25 (Internal Thread Connection) | DN40 (Internal Thread Connection) |

| Power Supply | 380V/3N/50Hz | 380V/3N/50Hz | 380V/3N/50Hz |

| Rated Input Power (kW) | 2.58 | 4.30 | 8.80 |

| Maximum Input Power (kW) | 3.8 | 6.3 | 12.8 |

| Rated Input Current (A) | 11.8 | 8.6 | 17.6 |

| Maximum Input Current (A) | 17.2 | 12.6 | 25.2 |

| Operating Ambient Temperature Range (°C) | -5 to 45 | -5 to 45 | -5 to 45 |

✅ Notes:

- All models use R22 refrigerant and are designed for industrial or commercial applications.

- The KFRS-100C model has significantly higher capacity and dimensions, suitable for large-scale hot water demand.

- IPX4 rating indicates protection against splashing water from any direction.

- Class I means equipment requires grounding for safety.

Let me know if you need this formatted as an HTML table, PDF, or with additional notes!